How To Choose Electrical Insulating Sheets

It is quite essential to know the insulation properties of the materials, including dielectric strength, compressive strength, tensile strength, pressure resistance, impact resistance, corrosion resistance, cryogenic resistance, and flame resistance. The below information will help you to choose sheet materials according to your application requirement. You can download the related datasheet here for your reference.

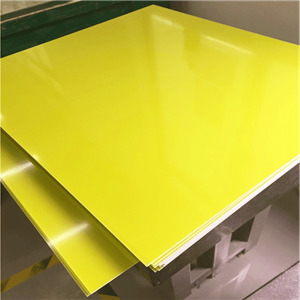

Epoxy Fiberglass Cloth Sheet

Insulation grade: B class

Thickness: 0.012″ – 5.9″

Dimension: 40″ x 80″, 48″ x 80″, 48″ x 96″

Epoxy fiberglass cloth laminated sheet is made of non-alkali fiberglass cloth for electrical purposes impregnated with epoxy resin and phenolic resin under heat and hot pressing with excellent dielectric property and mechanical property, strong mechanical processing property, and good moisture resistance.

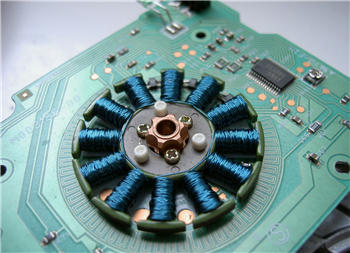

Due to its high mechanical properties at medium temperature, epoxy laminate is suitable for the high insulation structure of mechanical, electrical, and electronic components. It can be processed into various insulation accessories and insulation structural parts of types of equipment and can be used in a humid environment and transformer oil.

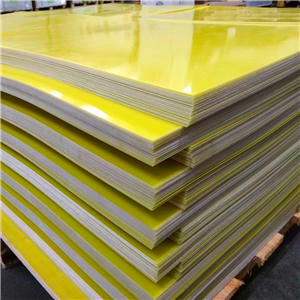

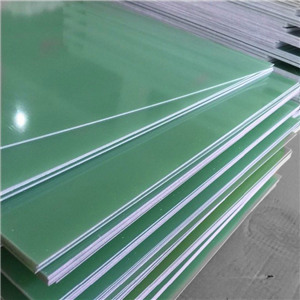

FR4/G10 Glass Fiber Sheet

Insulation grade: B class

Thickness: 0.0079″ – 5.9″

Dimension: 40″ x 80″, 48″ x 80″, 48″ x 96″

FR4/G10 Glass Fiber Sheet is a composite sheet material that consists of glass fabric, electrical grade epoxy resin. The epoxy material is extremely strong and stiff, has a low coefficient of thermal expansion, and has outstanding electrical properties. Epoxy resins are among the most versatile and widely used plastics in the electronics field, primarily because water absorption is virtually nil, rendering it an outstanding insulator.

Beyond its electrical insulating properties, epoxy resins exhibit great dimensional stability and superior adhesive properties. FR4/G10 has extremely high mechanical strength, good dielectric loss properties, and good electric strength properties, both wet and dry.

FR4/G10 glass fiber sheet has extremely high mechanical strength, good dielectric loss properties, and good electric strength properties, both wet and dry.

Phenolic Cloth Sheet

Insulation grade: E class

Thickness: 0.02″ – 4.0″

Dimension: 40″ x 80″, 48″ x 96″

Phenolic Cotton Cloth Laminated Sheet is a laminated material made by hot pressing of cotton cloths impregnated with a thermosetting phenolic resin binder.

Phenolic sheet has high compression strength and increased resilience, favorably lends itself to machining by drilling, cutting and forging. That is why it is widely used to make parts loaded with reversed electrical and mechanical stresses or working under friction (bushings, cams, etc.). Phenolic resin board is used as an insulating material for work in transformer oil and in the air at a normal relative humidity of the environment and at 50 Hz of frequency.

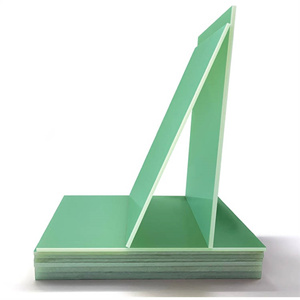

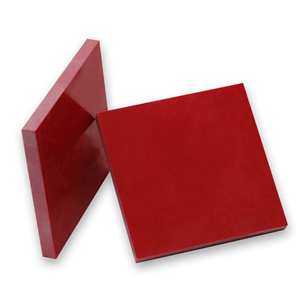

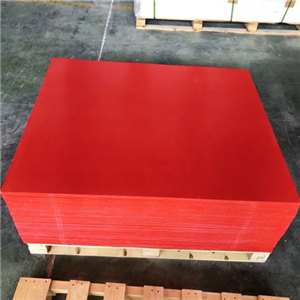

Multi-Color G10 Knife Handle Materials

Insulation grade: B class

Thickness: 0.012″ – 7.8″

Dimension: 40″ x 80″, 48″ x 80″, 48″ x 96″

G10 handle materials are made of electrical alkali-free glass fiber cloth dipped in epoxy resin, and processed by baking and hot pressing in the forming mold. Our G10 is first quality with good structure, absolutely no foreign matter or defects of any kind, very closed thickness tolerance, flat and straight panel, smooth and clean surfaces. It has a very bright color, good structure with a clear layer. Especially be suitable for Surfboard fins, Knife handle, and other sports appliances.

Colored G10 Epoxy Laminate can be made into Single colors or Multi-layered colors (G10 Mixed Color). Usual colors are available in Black, White, Red, Yellow, Blue, Orange, Olive Green, Gray, Brown, and more than 34 colors We also customize colors according to sample or color code.

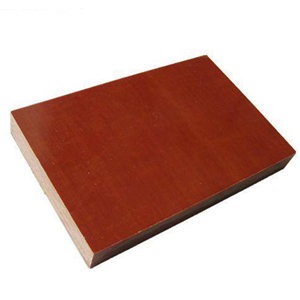

Bakelite Sheet

Insulation grade: B class

Thickness: 0.006″ -4.0″

Dimension: 40″ x 80″, 48″ x 80″, 48″ x 96″

Bakelite sheet laminates normally consist of fiber paper, cotton fabric, chemical fiber yarn, and fiberglass, etc. It is suitable for high-performance requirements of electrical machinery, electrical equipment as insulating structural parts, and transformer oil. Room temperature electrical properties with good machining performance with excellent electrical, mechanical, and processing properties.

The normally used Bakelite sheet Color is Orange and Black. Our Bakelite has high mechanical and dielectric properties, good heat resistance and wave resistance, and good machinability. It is widely used in motors, electrical equipment for insulation structure parts, PCB test rack, and etc.

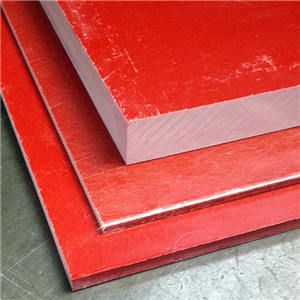

GPO-3 Thermoset Sheet

Thickness: 0.08″ – 3.94″

Dimension: 40″ x 80″, 48″ x 79″, 49″ x 98″

GPO-3 sheet is a glass-reinforced thermoset polyester sheet material. GPO-3 material is strong, stiff, dimensionally stable, and impact resistant. GPO-3 material also has excellent electrical properties including flame, arc, and track resistance. It is widely used for electrical insulating applications. GPO-3 sheet is also used for mechanical applications where strength, stiffness, dimensional stability, and relatively low cost are required.

GPO-3 also called Upgm203 is typically used in-phase and end barriers, insulation support, bus bar support, mounting panels, transformers, antenna bases, and spacers.

– GENERAL Applications 【Industries We Serve】the new energy industry

【Power Generation】

【Power Transmission】

【New Energy Industry】

Electrical insulation materials are used for preventing arcing in transformers, stabilizers, circuit breakers, etc. They can withstand insulating properties up to a specified electrical breakdown voltage.

In transformers, the dimensional stability and good dielectric features of the electrical insulation are crucial features. High voltage electrical transformers need insulating materials that can withstand high electrical and physical stresses. High-temperature insulation materials are particularly important to protect components from heat damage in the new energy industry

SERVICE & ADVANTAGE

Bulk Production

We have 2 factories and 5 production lines in China mainland and can produce different material types of insulation materials. Production capacity will meet the needs of different customers. If your demand is huge, we can start up 5 production lines to ensure the delivery time.

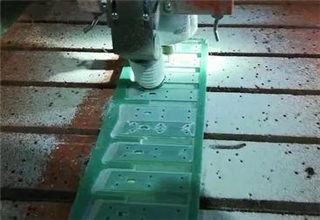

CNC Machining

We have everything you need to get custom machining parts. Our CNC machine shop that’s extensively equipped to produce your components economically regardless of order quantity. All you have to do now is give us your requirements and parts’ drawings. Our custom CNC machining service to make the part for you.

Packing & Shipping

In order to ensure that the goods are not easily damaged in transit, we use plywood boxes as outer packing. At the same time, our insulation material will be wrapped with a layer of PP film to ensure that the goods will not be affected by moisture. We use wooden cases or pallets with IPPC marks, which fully meet the import requirements.

The Process Flow & Duration Estimation

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

STEP1: Requirements Communication 1-3 Days

The first step is that we can talk about the thickness, customized size, temperature resistance grade, quantity, and all of your requirements. If you need machining parts, you can provide the drawings, tolerance range, and raw materials requirements to us. Then our engineers will check and reply to your every question so that you can understand clearly about our production planning.

STEP2: Sampling 1-3 Days

For purchasing insulation sheet materials, we will provide 1-2 pieces samples in A4 size for your testing. If you request machining parts, we will process samples according to the confirmed design drawing. Due to the processing difficulty, the time will be different. In general, a4 size sheet samples can be done within 1 day. And machining parts will be within 3 days. Then we will send them to you.

STEP3: Contract & Payment 1 Day

Once the details of the proforma invoice are confirmed by both of us, you can arrange the deposit for us according to the invoice. Meanwhile, we can also provide a Confidentiality Agreement, Quality Assurance Agreement, and International Trade Contract to you. Anyway, you will be safe in doing business with us.

STEP4: Manufacturing & Testing 15-20 Days

The bulk manufacture will be started according to the confirmed sample. We should prepare related raw materials and finish your order. After the end of production, our special testing department will test this batch of products and issue a quality certificate. Ensure that the quality of each product is up to standard before it leaves the factory. All will be finished in about 15-20 days.

STEP5: Shipping 10-15 Days

We will book the shipping space in advance while packing your order goods. The goods will be sent to the nearest seaport as soon as they are packed well. We know that due to the epidemic, booking shipping space is more difficult than before, and many cargo ships can not reach Chinese ports on time. Now what we do is to try our best to deliver the goods to the port on time, for saving your time.

A Brief Self-Nomination, Why Choose Us

- 2 Factories & 5 Production Lines

- Professional Team & Quick Response

- Factory Direct & Fast Delivery

- Manufactured Under ISO 9001 Quality Certified Program

- All Kinds of Data Sheet & Test Report Provided

- One-Stop Service of Electrical Insulation Materials

- Never Lower Quality, Though Raw Material Prices Rising

Dedicated Warehouse & Machining Workshop

Quality Assurance

Full refund your order money in case of bad quality

Low MOQ

For retailers,we accept small orders. It’s safe for first cooperation

Quick Delivery

5% discount for each week delay of delivery time.

Price Advantage

For distributors,buy in bulk can get a better price for saving cost.

The FAQs Throughout The Trading Process

XXX has been producing electrical insulation materials for 30 years and has encountered all kinds of problems. Here are the most important concerns of our customers before closing the deal.

Will you refund if the quality is not good?

Yes. It is confirmed. You need to provide photos of our products which are of poor quality for showing the details. Once confirmed by our engineers, the quality problem is caused by us. We will go through the refund process immediately, and discuss a refund agreement with you. This is our commitment to customers and confidence in our products.

How long does it usually take to receive the goods?

Depends on whether you want to do customization your insulation materials or not, and also depends on the speed of customs clearance and logistics. But we can guarantee to ship regular size materials in less than 7 business days. If you are in Thailand or Singapore, you will receive the goods in less than 2 weeks.

What are the payment options?

For new customers, we can accept the 30% T/T of the payment, and 70% T/T balance before the shipment. If you have been with us for years and run into cash flow pressure, we do offer OA credit.

Can you provide free samples for my testing?

We can provide 1-2 pieces samples of sheet materials in A4 size, or machining parts according to the confirmed design drawing. All are free of charge. But additional shipping charge will be on your side.

What if I don't know how to choose the material?

We have senior technical solution designers and professional technical consultants in the industry. They have over 20 years of industry service experience and will provide insulation materials customization services for you in electronics, electrician, for the insulation material extension various industries.

How to keep bulk production is the same as sample parts?

Generally, we will produce totally the same 2 samples of machined parts according to the confirmed drawings at one time. One will be sent to you for testing. If no problem after testing, our bulk production will be according to the other one sample and the drawings. All will keep precise as your requirement.

How can I know my order process after the payment?

From production to testing, from packing to shipping, our sales team will make a progress report for you every week and send pictures and videos for your reference. So that you can know every step progress clearly.

Can I come to China for factory inspection?

Of course, we welcome you to come and visit our factory. But now, it is better to wait until the epidemic subsides. So we support using ZOOM for online factory inspection. If you need the third party inspection, We will cooperate fully.

Can you replace goods that are damaged during shipping?

It happens on rare occasions because we ensure that all our products are well-packaged before being shipped. But in case it does, please contact customer care on the website. They will guide you and advise you accordingly.

How can you support me if I become your distributor?

We welcome you to become a distributor in your country. Your orders will be processed and shipped first. We will provide full support to you, including price discounts, pre-production, reasonable payment term, sampling, bid, exhibitions in your country. Contact us for more details.

How can I trust you and place the first order to you?

XXX has 30 years of experience in providing insulation materials and has built a better supply chain of raw materials. We can guarantee that our prices can be competitive with other suppliers in this field, and our service far exceeds your expectations. Contact our experienced team, our trust can be started from this basic conversation.

How can you benefit me if I make a deal of annual order?

For pricing, we will discuss it with you and fix a price for the whole year. It will avoid the risk of rising prices of raw materials. We can handle all the works, including trade stuff, clearance, and logistics, etc. Our sales team will keep you informed of the trade progress throughout. All you have to do is sit in the office and wait to receive the goods.